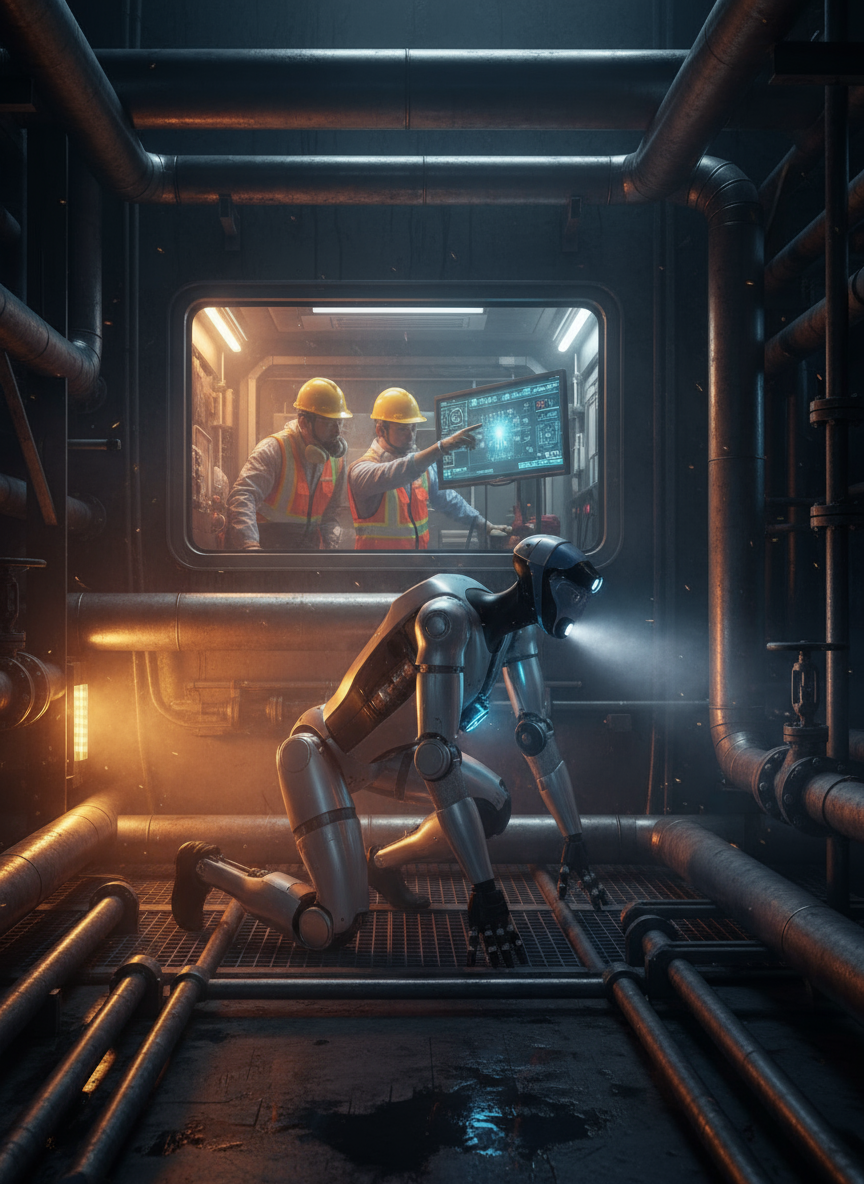

From inspections and logistics to construction and field maintenance, Asimov industrial robots deliver efficiency, safety, and measurable ROI.

Factories, plants, and construction sites are adopting robotics to cut downtime, improve worker safety, and accelerate productivity. From predictive inspections to automated intralogistics, Asimov connects organizations with solutions that redefine efficiency.

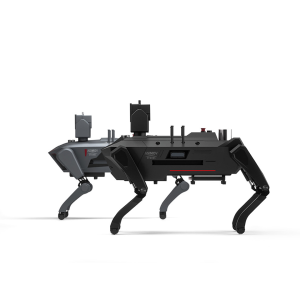

Tireless inspectors equipped with AI, vision, and thermal sensors to detect anomalies before failures occur.

Autonomous movers streamlining material flow, reducing forklift risks, and boosting throughput.

Rugged platforms assisting staff with checks, deliveries, and remote operations in hazardous sites.

Robots generating precise 3D data for digital twins, progress tracking, and safer work environments.

Industrial inspections are shifting from manual routines to continuous, sensor-driven monitoring. Robots equipped with LiDAR, vision, ultrasonic, and thermal cameras repeat inspection routes with precision, capturing anomalies like wear, leaks, or hotspots before they escalate. Unlike human rounds, robotic inspections generate standardized data that can be trended over time, ensuring earlier detection and higher reliability.

By automating these checks, organizations reduce downtime, protect staff from high-risk zones, and gain real-time visibility of asset health. Robots integrate with CMMS and analytics systems, producing digital reports, triggering work orders, and simplifying compliance. This transformation allows teams to focus on solving problems instead of searching for them.

Material handling has long been one of the most time-consuming and risky tasks inside factories and warehouses. Logistics robots move totes, pallets, and tools autonomously, reducing travel times and eliminating forklift accidents. Fleet managers orchestrate robot traffic, charging, and routing, while APIs connect them to WMS/MES systems to synchronize with production demand.

With adaptive navigation, robots reroute dynamically and adapt to evolving layouts without halting operations. This flexibility ensures smoother flows during peak loads, lowers congestion in aisles, and enables just-in-time supply chains. By removing inefficiencies, robots maximize uptime and create safer, leaner industrial environments.

Key benefits include:

Reduced travel time and fewer forklift-related risks

Flexible layouts with quick scaling for peak loads

Real-time integration with WMS/MES for just-in-time flow

Field maintenance robots provide safer and faster interventions, supporting checks, supervised tasks, and on-demand deliveries across large plants or remote sites.

When equipment is distributed across wide or remote areas, quick response and worker safety are critical to maintaining operational continuity.

These robots carry sensors, cameras, and payloads, streaming video, thermal maps, and diagnostics to enable technicians to triage issues remotely.

By providing real-time data, robots allow crews to arrive on site better prepared, reducing downtime and improving maintenance efficiency.

In hazardous settings—chemical, thermal, or high-noise—robots minimize human exposure. Over time, teams shift from reactive interventions to proactive maintenance planning.

Reduced exposure to dangerous environments

Faster troubleshooting with live video and diagnostics

Better prepared crews with shorter repair times

On complex construction and industrial sites, accurate and up-to-date mapping is essential. Construction and mapping robots provide reliable, automated data collection for efficient project management.

Robots equipped with LiDAR, SLAM, and photogrammetry tools scan environments consistently, producing data that supports digital twins, BIM, and site safety checks.

Their autonomous navigation guarantees repeatable paths, allowing weekly or daily scans to track site progress and detect potential issues early.

With accurate ground truth, project managers can measure progress transparently, detect clashes earlier, and reduce costly reworks.

Owners and EPCs gain clear visibility, contractors coordinate better, and overall project efficiency improves by bridging the gap between physical sites and digital models.

Consistent 3D scans for BIM and digital twins

Earlier clash detection and fewer reworks

Transparent progress metrics for all stakeholders

Robotics helps industrial players transform efficiency and safety. From predictive inspections to adaptive logistics, robots deliver standardized data, faster flows, and reduced risks. They integrate seamlessly into existing infrastructure and scale with business needs. Most organizations achieve measurable results within the first year—fewer disruptions, safer workplaces, and improved profitability.

Yes. All Asimov industrial robots are engineered for rugged conditions and built with IP-rated casings, industrial-grade batteries, and EMC compliance to ensure reliable performance in factories and outdoor environments. They are tested against dust, humidity, vibration, and temperature extremes to match the strict demands of manufacturing and construction sites.

Beyond durability, every model comes with certification packages that help organizations meet internal safety audits and external regulatory requirements. This documentation simplifies procurement, ensures compliance, and builds confidence for both operators and management when deploying robotics at scale.

Integration is a core design principle. Robots connect through APIs and middleware to leading warehouse, manufacturing, and enterprise systems, allowing seamless task assignment and status updates. This ensures that material movements, inspections, or deliveries align directly with production demand in real time.

During onboarding, our team maps your workflows into the fleet manager, runs dry-runs, and trains staff on monitoring dashboards. Once live, operators see robots as another connected asset in the digital ecosystem, removing silos and giving end-to-end visibility of plant operations.

Most organizations achieve ROI within 12–18 months, driven by lower labor costs, fewer forklift accidents, and reduced unplanned downtime. Robots eliminate repetitive travel, deliver standardized data, and increase uptime by detecting faults earlier and streamlining material flows. The result is improved OEE, shorter lead times, and measurable safety gains.

Financial impact is only part of the story. With robotics, plants also gain higher workforce satisfaction, stronger compliance, and a foundation for continuous improvement. By proving value quickly, companies can scale adoption site by site, creating compounding returns across the enterprise.

Yes. Our robots are designed for mixed environments, including dusty warehouses, humid plants, and outdoor yards with uneven terrain. Rugged exteriors, weatherproof components, and advanced navigation systems ensure reliable operation in rain, heat, or low light, while industrial-grade batteries guarantee long runtimes.

Navigation adapts to high-traffic zones and variable layouts. Safety scanners create protective fields around people and assets, while LiDAR and cameras manage complex routes. This makes them suitable for environments where traditional automation would fail, ensuring continuous performance in real-world industrial settings.

Yes. Industrial robots are designed to work alongside conveyors, lifts, and production lines. They use docking modules, transfer tables, or simple adaptors to hand off totes, pallets, or materials without requiring major layout changes. This compatibility ensures fast deployment with minimal disruption.

Our engineering team collaborates with your facility managers to align heights, safe zones, and handoff points. This phased approach allows robots to be introduced gradually while existing processes continue, minimizing risk and ensuring that ROI starts building from day one.

Maintenance is minimal thanks to modular design and predictive diagnostics. Robots monitor their own systems and send alerts for routine checks, battery replacements, or firmware updates. Standard programs include quarterly inspections and annual servicing, keeping downtime low and predictability high.

Most issues are resolved remotely, while on-site interventions are fast due to plug-and-play parts. Service data is integrated into your CMMS, ensuring asset history is complete. This proactive model reduces unexpected failures and extends equipment life, delivering consistent performance year after year.

Every deployment includes structured training tailored to industrial settings. Staff attend safety briefings, participate in guided route demonstrations, and run supervised shifts until confident. Standard operating procedures are provided for exceptions such as blocked paths, emergency stops, or manual overrides.

This approach ensures operators, supervisors, and maintenance teams all understand their roles in the new workflow. Within a few days, robots become a natural part of plant operations, reducing fear of adoption and building trust between human teams and robotic systems.

Yes. Flexible financing and leasing models allow organizations to adopt robotics without heavy upfront investment. Hardware, software, and support can be bundled into a monthly plan, aligning costs with the savings and efficiencies generated.

This approach makes robotics financially accessible while maintaining scalability. Companies can start small, prove value in one area, and expand step by step. Leasing reduces barriers to entry, ensures sustainability, and provides a path to long-term competitiveness in a rapidly evolving industrial landscape.

ASIMOV AI AGENT